Fruits and vegetables are subject to ethylene-accelerated decay. Microbes and metabolic enzymes are other sources of decay. All these can be dealt with! While refrigeration was the early frontier in maintaining foods for longer periods, ozone is today's best companion: it will reduce microbial loads and eliminate fungal spores and significantly extend shelf life.

Fruits and vegetables are subject to ethylene-accelerated decay. Microbes and metabolic enzymes are other sources of decay. All these can be dealt with! While refrigeration was the early frontier in maintaining foods for longer periods, ozone is today's best companion: it will reduce microbial loads and eliminate fungal spores and significantly extend shelf life.

Ozone can be used in various produce handling phases to contain and/or reduce contaminants. Storage areas, refrigerated and non, can be treated with ozono-treated ventilation systems. Washing and processing lines can use ozonoated water; ozone will negate the impact of earth-borne bacteria and mold-laden elements, thus getting the benefits simultaneously. Finally storage bins, machinery surfaces and cleaning tools can be sanitised as well.

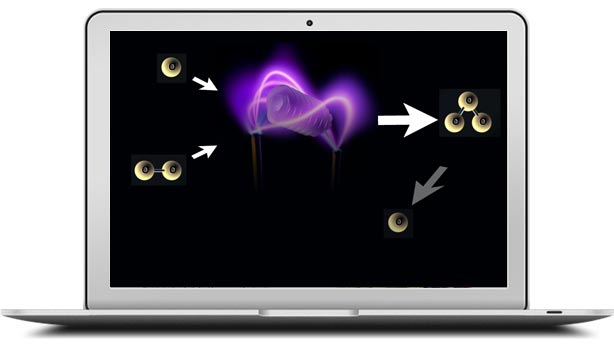

Ozone is superior to chlorine; its effectiveness is driven by better results against chlorine-resistent bacteria. Ozone is a molecule of oxygen, to which a third oxygen atom is attached. The new molecule - O3 - has powerful oxidising properties. It will attack pathogens, penetrate the walls of cells and proceed to destroy them from the inside. Chlorine has no impact on viruses; ozone, through this same cell-attack mechanism, does. And while ozone leaves no residues, chlorine can generate trihalomethanes derivatives that are proven cancer agents. When applied in proper doses, according to studied protocols, ozone carries no health risks for those working with it.

Ethylene cross-contamination between sensitive and producing sources is another concern. Ozone stops ethylene production. Thus, produce will remain firmer, appear fresher and maintain its taste for a longer period, than untreated produce.

O3 has a short half-life. This means that its effect is concentrated in a short period of time, then the third atom detaches itself and leaves regular O2 in its wake.

Absolutely. No. Residues.